Instructions for use

1- place unprocessed steam chemical integrated in each pack and place the pouch container system or tray into the sterilizer

2- process the load according to the sterilizer manufacturers instructions.

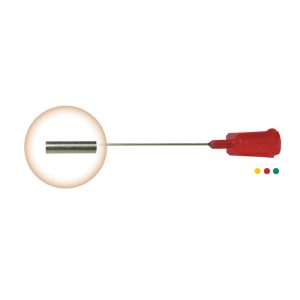

3- release the load if the dark bar on the screen chemical integrated as entered the blue ACCEPT area if the dark bar has not entered into the blue ACCEPT area do not release the load

Key Features

- Type 5 Chemical Integrator: Designed to monitor critical sterilization parameters, ensuring accurate results.

- Moving Front Technology: The clear visual indication, featuring a dark bar that moves across the indicator, confirms sterilization at a glance, eliminating the need for interpreting color changes.

- Universal Compatibility: These chemical integrators are suitable for use with gravity, pre-vacuum, and flash steam sterilizers, making them versatile across different sterilization setups.

- Eco-Friendly and Safe: Constructed without lead or latex, they reduce environmental impact and minimize allergy risks for staff.

Steam sterilization has been used for 100 years. decade of research have shown that the integrity of a steam sterilization process is the function of three basic parameters time, temperature and the presence of saturated steam all three are critical for effective steam sterilization.

The importance of saturated steam is faster sterilization than dry heat. for example dry heat sterilization required a sterilization time of 60 minute at 160 degree Celsius. while steam sterilization at the same temperature will take less than a minute. that’s why Sterieco developed class 5 steam integrated to measure 3 critical parameters